vane pump working

this article as website wizarticle The vane pump or hydraulic cartridge pump is used in the installation of many industrial systems with a maximum pressure of 200 bar.

The main advantages of cartridge pumps are free pumping and low noise generation.

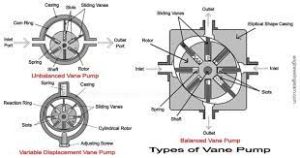

The rotor shaft is driven by radial blades mounted by an actuator or motor.

The generator ring is located in a circle in a centrifugal position, the degree of centrifugation determines the displacement of the pump.

When the centrifuge decreases to zero, the displacement of the pump is 0 cm3.

From that moment on, the pump does not pump any oil.

Suction and transmission:

The space between the blades is moved by the rotor. In the suction part,

the volume of these spaces increases and they are filled with suction line oil.

In the pressure part, the volume of these spaces decreases and the forced oil enters the pressure line.

**Click to buy a vane pump in Hydkala.com store**

Hydraulic vane pump structure

If we want to examine the hydraulic vane pump in terms of physical structure.

We must say that these pumps are made of one rotor and several blades.

Usually, hydraulic cartridge pumps are with one core, and this factor has caused the noise of these pumps to be low

, and in fact, this issue has become an advantage in relation to these pumps.

The blades are located inside the rotor and their movement is radial.

The speed of these blades can be considered from 1000 to 2000 rpm, even in some models, the speed of the blades reaches 2400 rpm.

The operation of the cartridge or hydraulic vane pump is free pumping,

and this is one of the other advantages of these pumps.

The volumetric efficiency considered for the cartridge pump is about 85 to 90%, which for the overall efficiency should be said to reach 75 to 80% due to leakage in the low rotor.

How the hydraulic cartridge pump works

If we want to talk about the operation of the cartridge pump,

we can say that when the hydraulic cartridge pump starts working,

the distance between the rotor and the rim increases in the first half of the initial rotation of the shaft,

resulting in volumetric expansion and the same expansion.

Volumetric pressure decreases and increases suction.

By creating suction, the fluid is transferred to the pump inlet.

In the second or second half of the cycle, the space between the vanes decreases,

causing the fluid to be directed to the outlet at a higher pressure.

In order not to create bubbles in the cartridge pump during this suction operation,

the suction part should be set to 0.1 or 0.2. The pressure created in the vane pump during this operation must be at least 0.8.

In cartridge pumps, the eccentricity can be adjusted manually by means of a cam ring.

Hydraulic pump cartridges use push pins or light springs to connect the blades.

The vane pump, like other pumps, is available in parallel and in series on the market.

To connect the series, the capacity of both pumps must be equal and in fact the output of one of the pumps must be the output of the other pump.

In fact, in this type of connection, pumping will be done with double the pressure.

Advantages of hydraulic vane pump

Due to the many advantages of cartridge pumps over gear pumps, today the use of this type of pump in industrial applications has become very common.

As you know, there are different types of pumps and each of them can be used in a part of the industry.

For example, we can mention the use of hydraulic pump cartridges in applications such as automotive, aerospace and fluid transfer.

Hydraulic vane pumps are commonly used as high pressure pumps in various parts of cars,

including the steering wheel, air conditioning and automatic pumps.