Seamless pipes Manufacturers in Pakistan are the most durable among all pipe types. due to the uniform structure throughout the pipe.

Seamless pipes can be made in very precise sizes and applications. However, there are limitations in making pipes with large diameters. Seamless pipes Manufacturers in Pakistan are widely use in the manufacture of pipe fittings such as elbows, and tops.

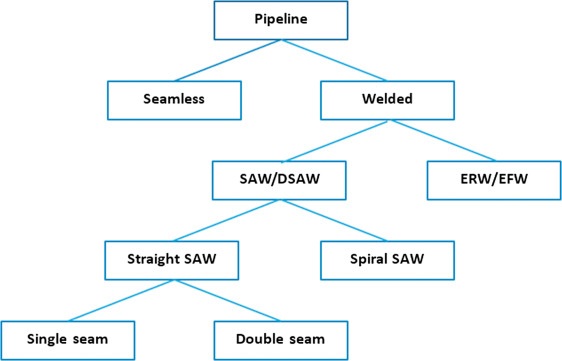

Details of various production processes

Spindle Milling Process

During the pipe manufacturing process The billets are heat to high temperatures in a rotary kiln. Cylindrical holes, also known as mother holes, are made with a rotary hammer and drum unit that hold the drill in the center of the shank.

The outer diameter of the hole is approximately equal to the inner diameter of the end pipe. With their help, it is possible to install secondary rollers of any outer diameter and thickness.

Mannesmann Tap Pipe Manufacturing Process

Mannesmann was a German engineer who invent the manufacturing process for this pipe. The only difference between conductive milling and arbor milling is how to spindle to the inner diameter in a single pass. Whereas the Mannesmann method allows for a number of steps to be reduce.

Forged Seamless Pipe Manufacturing Process

In Seamless pipes Manufacturers in Pakistan forging process The heating rods are place on the die head which has a diameter slightly larger than the diameter of the finish pipe. Cylindrical forgings are made with a hydraulic piston hammer with the same bore.

When the forging process is complete The pipes are machine to their final dimensions. The forge pipe manufacturing process is use to produce large diameter seamless pipes that are not made by conventional methods. Forged pipes are commonly use in steam manifolds.

Extrusion Process

In the manufacture of extrude tubes, heating rods are place in a mold. The hydraulic cylinder presses the spindle into the porous spindle. and the material flows out from the cavity of the cylinder between the die and the spindle. This will cause the tube to come out of the penis.

Seamless pipes Manufacturers in Pakistan can produce thick pipes call hollow pipes. Many secondary tube manufacturers use this hollow scalpel to make tubes of different sizes.

Welded Pipe Manufacturing Process

Weld pipes are made from bond plates, coils, or strips. In the manufacture of weld pipes, the first plate or coil is roll into a circular cross section using the plate or coil in a continuous process.

Once the circuit rolls off the breadboard, the tube can be weld with or without filler. Weld pipes can be manufacture in large sizes without restrictions. Filler pipe welding can be use for large bends and arcs.

Compare to seamless tubes, weld tubes are also cheaper due to the smoothness of the weld.

There are Several Methods of Welding. Use for Pipe Welding

VPV Resistance welding

EFW-Electric Welding

HFW-High Frequency Welding

SAW-Underwater Arc Welding (Long and Spiral Stitch)

ERW Pipe Manufacturing Process

During the manufacture of ERW / EFW / HFW tubing, the first plate becomes cylindrical and the longitudinal ends of the forming rollers are weld by welding. Low frequency resistance welding High frequency induction welding or high frequency resistance welding.

SAW Pipe Manufacturing Process

Submerge arc welding uses an external metal as a filler. (Electric wire) For joining mold panels. Depending on the size of the tube, the SAW tube can have one or two vertical joints.

The SAW tube can also be use for spiral seams that are continuously wound from a coil sheet. Seamless pipe in Pakistan offer much higher performance than SAW tubes. However, SAW screw tubing is only use for low pressure systems such as water and industrial processes. Waste generation, etc.