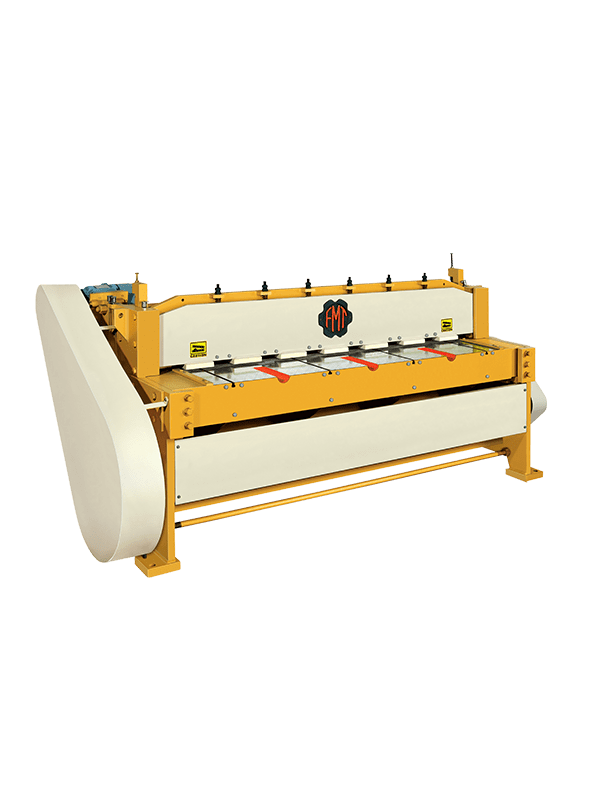

Shearing machine there are four significant strategies used to shape sheet metal:

- bowing

- shearing

- rolling

- turning

Sheet metal part

The initial phase in creating a sheet metal part is slicing to measure. Shearing machines and shearing apparatus fill this role. Shearing machines are multipurpose gadgets utilized in the cutting of amalgams and other sheet metal. Some shearing machines utilize a scissor-like, precise shear activity to cut metal into sheets or strips. Other, bigger machines utilize a straight shear activity with the edge fixed at a point instead of the precise development.

Shearing tasks

Shearing tasks are performed by the activity of two edges, one fixed in the shear bed and the other moving upward with next to zero freedom. Shear activity moves continuously from one side of the material to the next. The rakish design of the sharp edges is known as the rake. Both rake and freedom are an element of the sort and thickness of the material to be cut. In press type shears, the upper cutting edge leans according to the lower edge, around .5 to 2.5 degrees.

The material set up

The common shear comprises of a proper bed to which one edge is mounted. an in an upward direction propelling crosshead, and a progression of hold-down pins or feet that hold the material set up while the cutting happens. A checking framework with stops is utilized to deliver explicit workpiece finish sizes. Explore hydraulic shearing

Types

There are a few kinds of shearing machines that can utilize to meet your particular work needs. Air/pneumatic shears utilize a pneumatic chamber to control the crosshead and upper cutting edge. Hydraulic shears are driven or fueled by a hydraulic powered chamber. Hydraulic powered presses can create incredibly high powers to cut metals or different materials.

Manual shears

Hydromechanical shears drive by a hydraulic pressure chamber or hydraulic pressure engine. Mechanical shears have the moving edge drive by a revolving engine through a screw, switch. Or another system. Shears drive by an immediate association with a servo engine. Manual shears drive or fueled the hard way or with manual power that amplify with a screw, switch, or another instrument.

Highlights

Limit/working power is the working press load needed to cut a section during creation. The evaluated limit of a press is the strain, in tons, that the slide or slam will securely apply at the lower part of the stroke while working inside the scope of the press. Stroke is the smash travel from top flawlessly focus to base right on target. Stroke speed is the straight speed of the slide or slam during squeezing or smash headway steps.

Sheet metal Specifications

When indicating and buying metal shear hardware. Significant thought is the necessary aspects expect to accommodate your scope of workpieces.

Sheet/stock thickness is the sheet or web thickness that can sheare.

Sheet/working length is the biggest element of working separation from right to left that can cut.

Throat profundity is the separation from the centerline of the slam to the back outline in a hole outline, C casing, or comparable press type.

Working a shear requires severe adherence to security techniques. Machine administrators can actuate the shear utilizing a few techniques.

Manual activity

Manual activity controls physically through an administrator interface gadget. For example, a footswitch, pendant, or press button controls.

Programmed/ordering units naturally load parts into the framework and work without administrator intercession. The machine changes or changes tooling and different boundaries, like speed or applied burden, in a pre-modified way. A few robotization prospects incorporate CNC control or a PLC regulator. Which utilize to program and play out an arrangement of procedure on the press.

Shearing machines

Shearing machines require occasional support. Shear edge honing should perform consistently so that shears don’t yield low-quality cuts. What’s more, the legitimate hardware should utilize for shear honing. With shear sharp edges. The point of the bleeding edge and the completion of the toil are significant variables in deciding shear execution and life span. Frequently, providers of shears and shearing hardware might give an upkeep plan and give new parts and honing administrations.

Read more: How to Choose the Right Lethbridge Excavation Contractors