E-book Library E-books that will help you get began and succeed with collaborative industrial robots automation. Whether you are a first-time buyer or experienced in automation, our sales representatives and robot technicians may help you select the best industrial robotic to fulfill your application necessities. In the 1980’s, automotive corporations showered robotic companies with investments.

RobotWorx provides an off and on-site preventive maintenance service to maintain robots operating at full capacity. The invention of the Numerically Controlled machines, the popularity of the pc , and the built-in circuit all helped to make it potential to begin to develop the very first, yet simple, industrial robotic. This introduced with it an growing demand for manufacturing and consequently, motivation for automation. Today’s labor market includes fewer skilled manufacturing staff because of many years of offshoring, and robots get rid of the shortfall.

Repeatability

It is often the most important criterion for a robot and is just like the concept of ‘precision’ in measurement—see accuracy and precision. This is then quantified utilizing the standard deviation of these samples in all three dimensions.

Using a graphical person interface the programming is done by way of drag and drop of predefined template/building blocks. They usually characteristic the execution of simulations to judge the feasibility and offline programming in combination. If the system is ready to compile and addContent native robotic code to the robotic controller, the user not has to learn each producer’s proprietary language.

Therefore, a method for safety even if the robot contacts a human should be considered. The method of Camera-Space Manipulation has received considerably less consideration than other vision-based strategies for manipulator management such because the visible servoing methods. My withdrawal is not going to have an result on the right to course of my knowledge as much as the time of withdrawal.

Kinds of collaborative robots

There is appreciable variance in the kinds of collaborative robots meeting the above specs, and the level of contact between robotic and worker in collaborative applications.

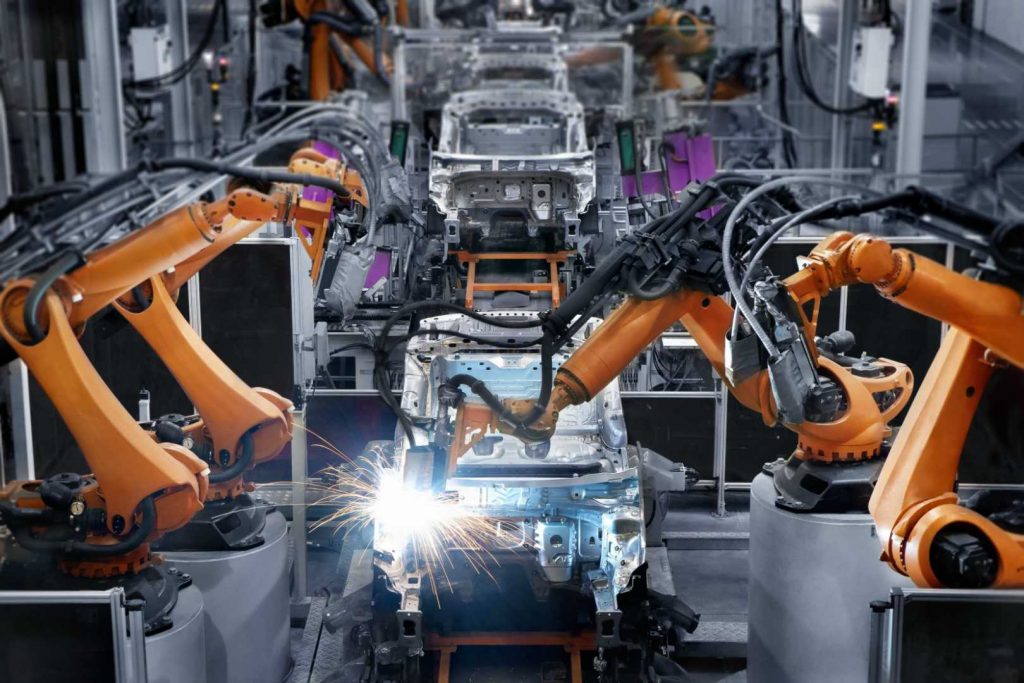

Moving quickly and precisely, robots handle parts too small for human eyes and fingers and never make errors. That’s one reason growing numbers of products are designed for robotic meeting from the outset. The mostly used robot configurations for industrial automation, embody articulated robots, SCARA robots and gantry robots. These work on three linear axes utilizing the Cartesian Coordinate system , that means they use three sliding joints to maneuver up and down, in and out and aspect to side. The cartesian robotic is essentially the most commonly used industrial robot, typically for CNC machines or 3D printing. There are greater than five types of industrial robots, but the commonest ones can be classified by their mechanical structure, based on the International Federation of Robotics.

A year later, we can look back and see what manufacturers have learned about how to adapt and succeed in the face of adversity. Collaborative robots are straightforward to program, fast to deploy, and safe to make use of. Cobots are solving labor issues in manufacturing operations in corporations of all sizes.

OEMs

This is very true for automotive OEMs that can incur excessive interruption prices if their production lines are down. One type of enter might come from the human interface gadget, corresponding to a educate pendant.

Nowadays, it’s highly unlikely to see any hydraulic robots in the market. How well the robot will return to a programmed place.

Find a Distributor UR has a worldwide distributor and companion network, prepared that can assist you solve your automation challenges. Maintenance and repairs are important for extending your robotic’s life cycle and maintaining downtime to a minimum. We provide various options to assist clients buy a robotic or robotic system. Knowing your price range is step one in making the best determination for successful integration.

Sales of recent robots grew slightly at zero.5% regardless of the worldwide pandemic, with 384,000 items shipped globally in 2020. This is the third most profitable yr in history for the robotics trade, following 2018 and 2017.

Important statistics

In the following 4 chapters, you’ll quickly discover the 34 most important statistics referring to “Industrial robots worldwide”. A variety of commonly used AI techniques and their functions in numerous areas of engineering are presented.

Material dealing with robots are utilized to move, pack and choose merchandise. They can also automate features involved in the transferring of parts from one piece of equipment to another. NOR Flash is the perfect memory for code storage in embedded methods due to its quick, random learn performance. Persistent RAM merchandise, such as F-RAM, nvSRAM, and MoBL® Asynchronous SRAMs with on-chip ECC are suitable for robots methods that require the best standards of reliability and efficiency.

The market share of the Chinese robot suppliers decreased from 31 p.c in 2016 to 25 p.c in 2017. In the previous, robots were asked to do very specific duties, often in a hard and fast location.

Robot investments are becoming increasingly worthwhile and hence turn into more and more widespread within business. MiR AMRs address a variety of workflows for small and mid-sized manufacturers to giant manufacturing and distribution centers.

In the context of general robotics, most types of industrial robots would fall into the class of robotic arms.